Autoclave cooling (after liquid programs)

Request a price

As soon as the set sterilization time has expired (usually 20 minutes for liquids), the heating is switched off and the system starts to cool down

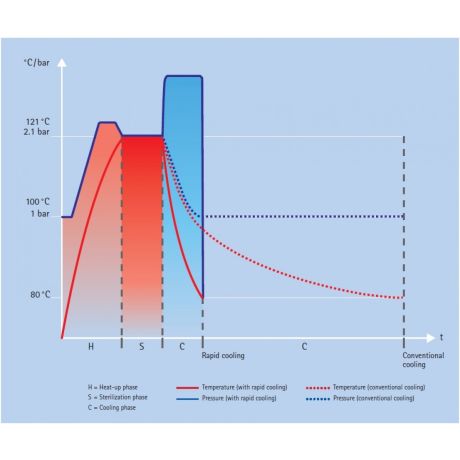

Indications of the graph:

- H = heating stage

- S = sterilization phase

- C = cooling phase

Due to safety regulations, the door can only be opened below 80 °C.

Since the autoclave is equipped with thermal insulation, an approx. An autoclave filled with 20 liters of liquid reaches the door-opening temperature only very slowly with self-cooling.

The more liquidwe fill the autoclave with, the slower it will cool down, so depending on the filling, it can take up to 4-6 hours.

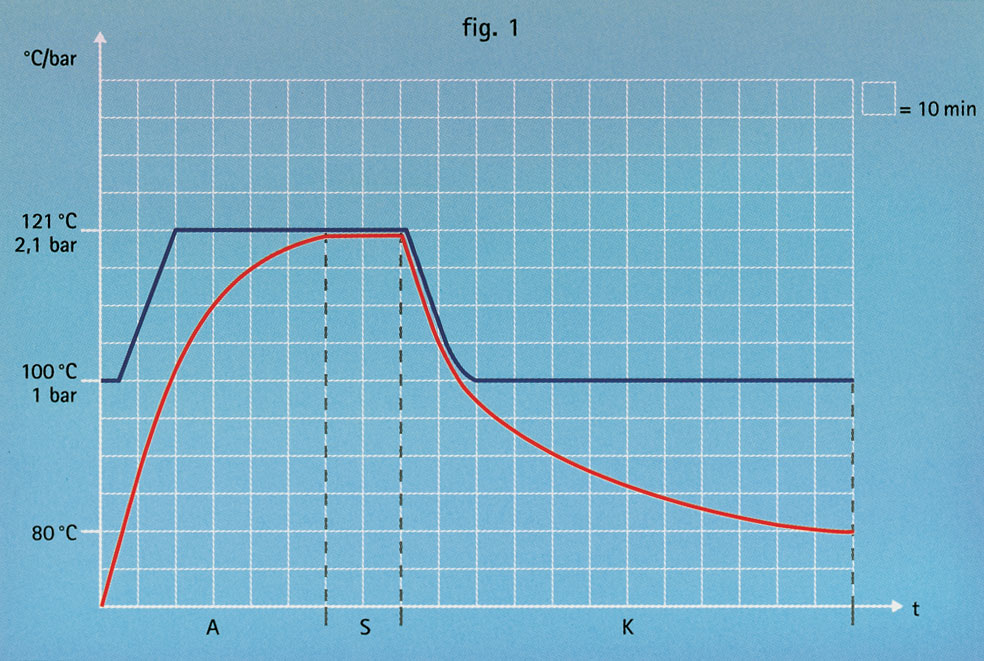

Slow (self-cooling) cooling of a traditional autoclave (with liquid program)

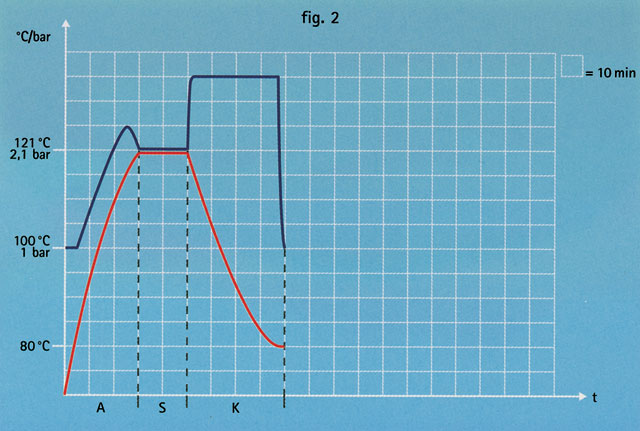

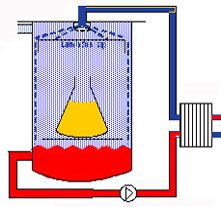

Rapid cooling of the Systec autoclave in the liquid program

After sterilizing liquids, the cooling time of the system can be significantly reduced in the following way.

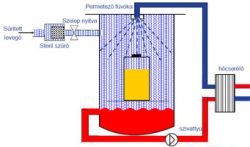

Stages of rapid cooling:

- Water cooling with compressed air support

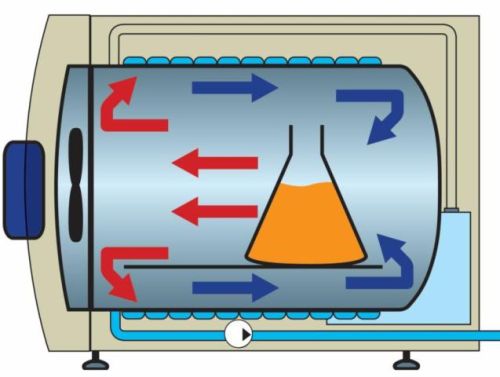

- Air mixing with an internal fan

- Heat exchanger built under the fan

Rapid cooling affects the length of section "K" shown in the diagram below. The four-square section becomes shorter by one square with each new step.

Spray cooling is one of the most efficient types of rapid cooling. Of the three elements above, only compressed air support is used. Unfortunately, it cannot be used for all applications. The degree of effectiveness is the same (or better), sample above three elements together.

Systec's system is also faster in the heating phase, because with the increased pressure, the temperature also rises much faster (due to the temperature-pressure curve of the steam). As soon as the temperature reaches the set sterilization value, the device suddenly reduces the pressure and the sterilization phase can begin. This technique is a basic feature of all Systec autoclaves. With the different rapid cooling options available for the X and E series, the cooling stage (K) can also be drastically reduced.

related products

Acceleration of cooling after liquid programs with internal fan mixing. It only works together with spiral cooling!

More informationsThis rapid cooling uses the principle of evaporation of the sterilized liquid, so some liquid loss (5 - 10 %) must be expected.

More informationsExtra fast cooling, cools down a 150-liter autoclave in about 10-15 minutes, in which approx. 40 liters of liquid were sterilized.

More informationsIf the autoclave already has spray cooling, but the bottles must not be sprayed directly.

More informationsThanks to the compressed air support, the bottles can be filled up to their nominal volume, and there is no loss of liquid from the tubes and flasks.

More informations