Autoclaves and steam sterilizers in the laboratory

Request a price

In microbiological or biotechnological laboratories, it is required to sterilize the tools, liquids, auxiliary materials and various samples used for work, as well as to destroy unnecessary or dangerous materials. Autoclaves are used for these tasks.

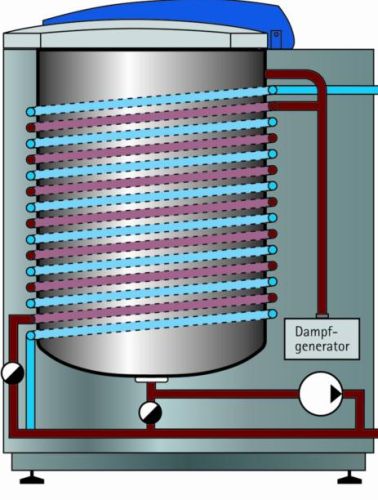

Sterilization takes place in the closed chamber of the autoclave with pressurized steam. Steam is ideally generated in the steam generator.

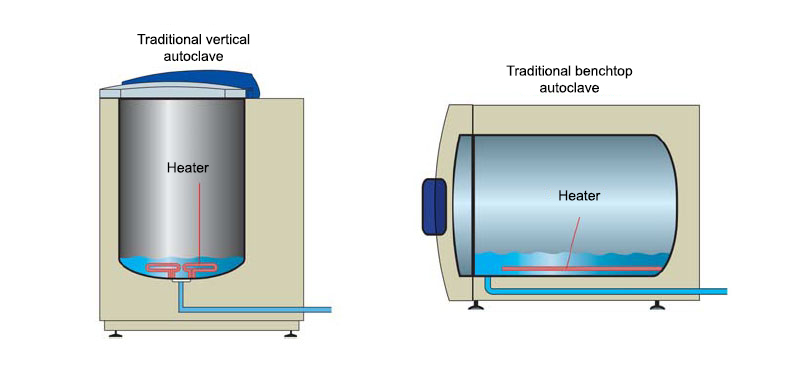

In the beginning, the autoclaves were all vertical chambers (top-loading), but nowadays benchtop versions (horizontal/front-loading) are also common:

What is the advantage of steam sterilization (autoclaving) compared to hot air sterilization?

Sterilization requires a lot of energy. The energy of steam is several thousand times greater than that of air. Think about the operating temperature difference between a wet/dry sauna and the feeling of heat: in a wet sauna, a certain degree of heat already feels very burning, while the same temperature (or even higher) is much more tolerable in a dry sauna.

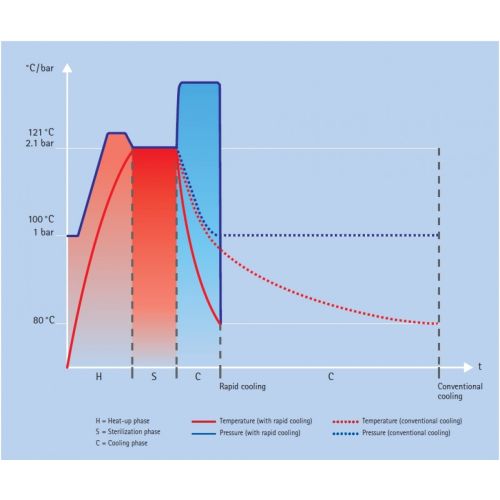

The advantage of sterilization with an autoclave is that the process takes place in a much shorter time thanks to the high energy of the steam. Another advantage of steam sterilization is the relatively low sterilization temperature (121oC and 134oC), instead of the 160-180oC used in hot air sterilizers. The use of hot air sterilization is often limited by the temperature tolerance of the devices.

Sterilization of liquids and culture media is not even possible with a hot air sterilizer, because the liquid evaporates (boils) in the open system. Liquids can only be heated to the sterilization temperature in a high-pressure device, i.e. in an autoclave.

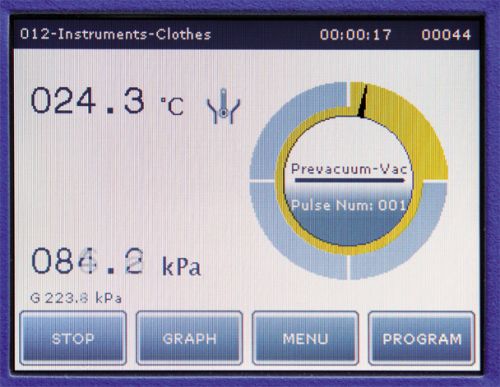

In order for the devices or samples to become truly sterile, they must be kept at a certain temperature for a minimum time specified in the protocols. The most common autoclaving protocol is holding at 121°C for a minimum of 20 minutes. Another commonly used method is sterilization at 134°C for 3 minutes.

The traditional method of producing steam in an autoclave and its challenges:

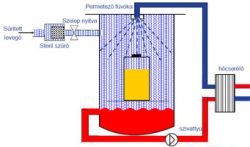

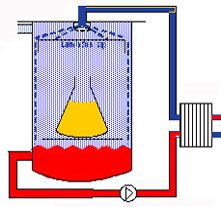

In most autoclaves that work with traditional technology, the steam is produced in the chamber itself. In this case, there is always water at the bottom of the chamber, and this water is heated by the heaters located at the bottom of the chamber.

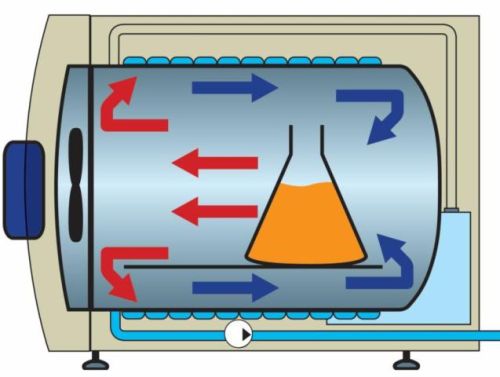

The main enemy of steam sterilization is air trapped in the autoclave. Where air remains, the steam cannot release the high energy required for sterilization. If the air in a hollow sample, e.g. in an empty glass container, in a pipette tip box, or inside a porous material, then the minimum time and temperature requirements stipulated in the protocol are not met, so we can be sure that our sample has not become sterile! Sterility is ensured by the so-called can be verified with biological indicators.

The arrangements shown in the picture represent the old (traditional) method, and their main disadvantage is that the removal of air is very difficult. The water occupies the lowest point of the device, so the air can only be removed from the device at a higher point. Since air is heavier than steam, the natural movement of air is downward in the chamber, so some of it remains inside the device.

In autoclaves with such heating, even a vacuum pump cannot achieve perfect results (remove air 100%), because after the first – relatively good – vacuum cycle, the second one will be less effective due to the continuous evaporation of the water at the bottom of the chamber.

But how can this problem be overcome? On the following page, we present the technical solutions used by today's modern autoclaves to achieve perfect sterility. >>

related products

Esential components of a validable autoclave: steam generator, vacuum system

More informationsSystec has the widest range of laboratory autoclaves: desktop, freestanding and cabinet (HX series), top quality laboratory autoclaves.

More informationsVX-series devices include a steam generator as standard. These are autoclaves without compromise. Vertical laboratory autoclaves from 40 to 150 liters in volume.

More informationsDesktop steam sterilizer for a volume of 40-200 liters.

More informationsBuild into a wall autoclaves of 90 - 1,580 liters for serving cleanrooms or for disposing materials in BSL2, BSL3 and BSL4 laboratories.

More informationsChoice of chamber diameters: 740 and 1000 mm, net volume from 320 liters to 1580 liters, a total of 16 autoclaves of different sizes

More informationsThe self-cooling of the liquids - due to the thermal insulation of the autoclave - only happens very slowly. Faster access to the sample can be achieved by rapid cooling.

More informationsThanks to the compressed air support, the bottles can be filled up to their nominal volume, and there is no loss of liquid from the tubes and flasks.

More informationsAcceleration of cooling after liquid programs with internal fan mixing. It only works together with spiral cooling!

More informationsThis rapid cooling uses the principle of evaporation of the sterilized liquid, so some liquid loss (5 - 10 %) must be expected.

More informationsExtra fast cooling, cools down a 150-liter autoclave in about 10-15 minutes, in which approx. 40 liters of liquid were sterilized.

More informationsIf the autoclave already has spray cooling, but the bottles must not be sprayed directly.

More informationsSpecial Systec autoclaves for preparing media up to a useful volume of 10 - 120 liters

More informations