Compressor for autoclave

Systec

Request a price

If the autoclave has a rapid cooling system that uses water, we can produce the necessary compressed air with a silent oil-free compressor. The compressor operates fully automatically. This is also called rapid cooling with support air.

Autoclaves of different sizes require different amounts of compressed air for rapid cooling.

The compressor produces 55 liters of air per minute.

The devices of the HX series with a chamber diameter of 740 and 1,000 mm require compressed air even without water cooling, because this is the only way to remove the condensate collected at the bottom of the autoclave.

If the autoclave is to be serviced with the lab's own compressed air, the pressure of the compressed air must be >5.6 bar!

related products

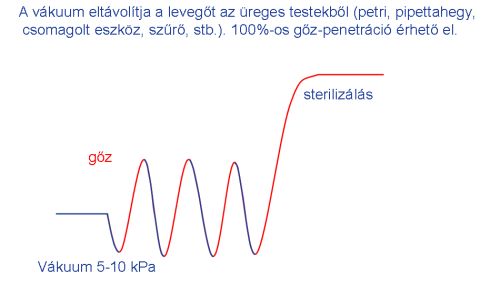

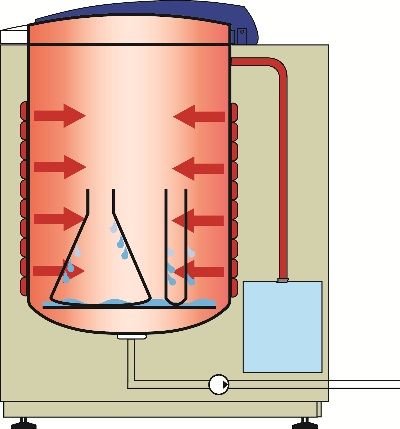

Desktop steam sterilizer for a volume of 40-200 liters.

More informationsChoice of chamber diameters: 740 and 1000 mm, net volume from 320 liters to 1580 liters, a total of 16 autoclaves of different sizes

More informationsBuild into a wall autoclaves of 90 - 1,580 liters for serving cleanrooms or for disposing materials in BSL2, BSL3 and BSL4 laboratories.

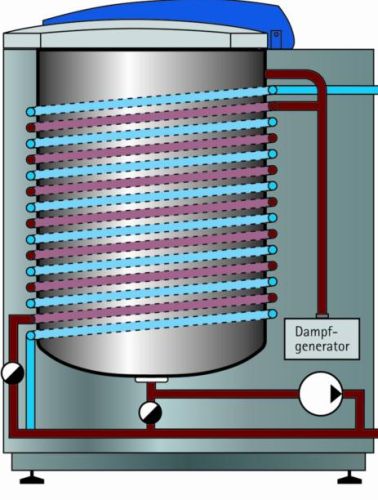

More informationsVX-series devices include a steam generator as standard. These are autoclaves without compromise. Vertical laboratory autoclaves from 40 to 150 liters in volume.

More informationsTo completely remove the air, to reduce the stench that occurs during slaughter, into the autoclave that can be validated.

More informationsDrying in Systec mode: SUPERDRY = vacuuming + filtered air rinsing + subsequent energy input.

More informations