Positive pressure water filter

Request a price

A significant acceleration of the filtration of sedimentary waters becomes possible by using a pressure filter operating at several times the atmospheric pressure.

A sample that has been vacuum filtered for approx. They were filtered for 4 hours ("four-hour sample"), with the overpressure filter, with a pressure of 3 bar, it could be filtered within 1 minute!

Depending on the further investigation, air produced by a compressor or stored in a bottle, or even other (inert) gas can be used for filtration.

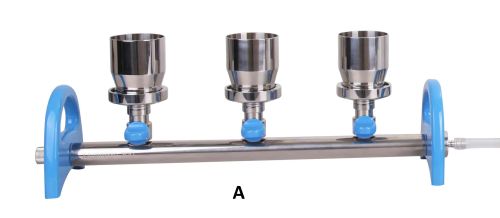

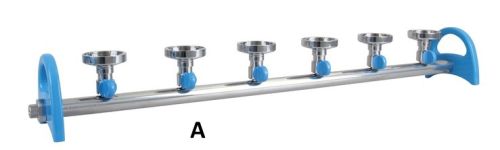

We make positive pressure filters in two versions:

- We produced it with a 250 ml filter housing, but originally without a filter housing holder (the black disc on the right side of the pictures). This type was the original design. Of these, we only have 1 3-seater stand in stock. In the new version - which already includes the "discs" holding the filter housing - we only make filter stands with 1, 2 and 3 workplaces. The filter housing holder is a circular surface on which the opened filter housing removed from the stand can be placed - without removing the pressure hose. Such a filter stand can have a maximum of 3 workplaces, because it would be too wide if there were more workplaces.

- with a 1.25-liter filter housing (new type), 1-2-3 workplace design (see pictures 4 - 6). In one of the pictures showing the 1.25 liter filter stand, you can see the filter housing of the opened pressure filter being placed on the filter housing holder. The device can also be used for sterile filtration if it has been previously sterilized by autoclaving and the operating gas has also been properly filtered.

The maximum operating pressure of the pressure filters: 6 bar for the 250 ml volume, while 8 bar for the 1.25 liter one.

Structure:

The filter unit is mounted on a strong steel stand, the length of which is determined by the number of workplaces. The surface treatment of the stand enables working in wet environments.

The volume of the sample space of the smaller pressure filter is 250 ml, the material of the filter housing is polycarbonate, which is surrounded by a protective mask made of metal. All fasteners are made of stainless steel. The piping is easy to detach and connect.

Each workstation has a separate control valve and manometer. The leak-proof closure of the individual elements is ensured by rubber rings ("O" rings).

The tank of the new 1.25 liter pressure filter is made of stainless steel.

The working principle of the pressure filter with a 1.25 liter tank is the same as the pressure filter with a 250 ml tank, the main difference is in the volume of the filter tank. Another novelty is that when the filter housing is opened, the tube does not have to be removed from the tank, but the tank can be placed on a handy stand when replacing the membrane or cleaning the frit.

Operation:

For filtration, a filter paper or membrane filter with a diameter of 47-50 mm must be placed on top of the porous disc (frit) in the housing of the filter unit. The sample must be added through the vertical opening at the top of the filter container, which is then closed with the closing screw with the "O" seal.

The inner diameter of the filling opening is 11.5 mm, so a suitable sized funnel can also be used to fill the filter housing.

After closing the filter housing, the equipment can be pressurized with the pressure control valve and filtration can be performed.

The filtrate can be collected in a container placed on the stand - under the filter unit. If required, a pipe can be connected to the lower outlet of the overpressure filter, and the water / other liquid can be collected in a larger container. The outer diameter of the spout is 12 mm.

Maintenance:

The design of the water filter enables quick work and easy cleaning. The bottom of the filter housing can be removed from the stand with one movement and washed in the sink. If necessary, the filter housing can also be detached from the stand with one movement (the pressure pipe is quick-connect and easy to release), so it can also be washed.

No tools are required to disassemble and assemble the device.

| Technical data: | LSV-M | LSN-M |

|---|---|---|

| Sample space volume: | 250 ml | 1,25 liter |

| Max recommended pressure: | 6 bar | 8 bar |

| Filter surface: | Ø50 mm (20 cm2) | Ø50 mm (20 cm2) |

| Filling hole size: | Ø11.5 mm | Ø11.5 mm |

| Spout size: | Ø12 mm (olive) | Ø12 mm (olive) |

related products

Filter stand made of stainless steel

More informationsThe conventional diaphragm pump can produce a vacuum of 100 mbar. In pressure mode, it is capable of up to 7 bar pressure. Thanks to the membrane technology, the produced air is clean (oil-free).

More informations