-

Instruments, devices

-

Stirrers, shakers, centrifuges

Magnetic stirrers Overhead stirrers Stirrers, shakers Centrifuges FlocculatorsHeating and thermostatic devices

Heating plates Block heaters, digestion units Heating mantles Circulating thermostats Drying ovens, hot air sterilizers Incubators Vacuum drying ovens Climate and test chambers FurnacesRefrigerators and freezers

Refrigerators, freezers ULT freezers Portable coolers Ice makers Recirculation coolersEvaporating and water distilling devices

Water baths Rotary vacuum evaporators Water distillers Kjeldahl Distillations Water purifiersAnalyzers

Mercury determining device Protein determining device Fat determining device Fiber analyzers Chromatographs Element analyzers Thermogravimetry TGA

-

-

Glassware

-

Plasticware

-

-

Metalware

-

Safety, hygiene

-

Filtration

-

Liquid dispensers

-

Sample preparation

- Microwave

-

Microbiology

-

Standards

-

Instruments, devices

-

Stirrers, shakers, centrifuges

Magnetic stirrers Overhead stirrers Stirrers, shakers Centrifuges FlocculatorsHeating and thermostatic devices

Heating plates Block heaters, digestion units Heating mantles Circulating thermostats Drying ovens, hot air sterilizers Incubators Vacuum drying ovens Climate and test chambers FurnacesRefrigerators and freezers

Refrigerators, freezers ULT freezers Portable coolers Ice makers Recirculation coolersEvaporating and water distilling devices

Water baths Rotary vacuum evaporators Water distillers Kjeldahl Distillations Water purifiersAnalyzers

Mercury determining device Protein determining device Fat determining device Fiber analyzers Chromatographs Element analyzers Thermogravimetry TGA

-

-

Glassware

-

Plasticware

-

-

Metalware

-

Safety, hygiene

-

Filtration

-

Liquid dispensers

-

Sample preparation

- Microwave

-

Microbiology

-

Standards

RETSCH RM 200 mortar grinder

Retsch

Request a price

The ancestor of this device was made in 1923. This was called the RETSCH grinder. The operating principle is the same, of course combining it with today's technology. In fact, it is an automated version of the mortar, which can be used very well for grinding and homogenizing medium-hard, soft and wet materials to an analytical fineness, such as e.g. tablets, slag, oil seeds, soil samples, spices, etc. For the basic device, you can choose seven types of mortars and pestles with the most suitable material for the sample to be ground. The reproducible results are ensured by the adjustable breaking pressure and positionable scraper. The task of the latter is to ensure that the material to be ground is always between the crusher and the mortar. The device has a digital timer. The LED display indicates not only the remaining time of operation, but also the rubbing torque. This helps to set the breaking pressure to the most suitable position. The reduction in grain size can be monitored on the inspection window above the grinding area. The device is easy to clean, the mortar and pestle can be replaced without tools.

RETSCH RM 200 type mortar grinder specifications:

| Specifications: | RM 200 |

|---|---|

| Material feed size: | < 8 mm |

| Final fineness: | < 10 μm |

| Sample volume max: | 190 ml |

| Speed: | 100 rpm |

| Power consumption: | 130 Watt |

| Dimensions: | 400 x 480 x 370 mm |

| Weight: | 24 kg |

related products

The mortar and pestle for the RM 200 device can be made of seven different materials

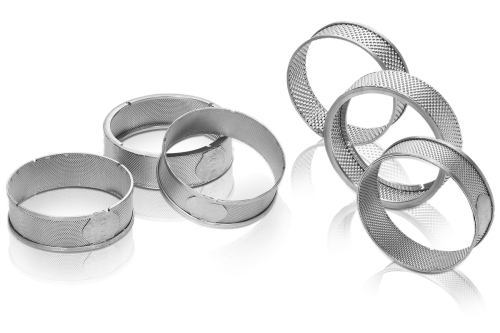

More informationsRing sieves for ZM 300 type mill. Material: stainless steel,stainless steel with a wear-resistant coating, or titanium.

More informations