RETSCH ZM 300 type ultra-centrifugal mill

Retsch

Request a price

The ZM 300 type mill can be widely used for soft, semi-hard, hard, brittle and fibrous samples.

The touch screen display enables simple user-friendly operation.

Adjustable parameters: grinding time and rotor speed. The grinder has an extremely powerful motor, which ensures that the sample can be ground in a very short time.

Grinding is carried out by a rotor consisting of several knives (teeth), rotating at high speed, and a stationary circular screen surrounding it. The teeth shred the sample, which passes through the circular sieve into the collection container. After grinding, the sample can be easily removed together with the collection container (cassette).

The grinder is easy to clean, the rotating rotors and circular sieves in the device are replaceable, so the particle size of the final product can vary over a wide range.

Recommended combinations depending on the quantity of the sample:

- for normal use, the 900 ml collection cassette (accessory), or one of the rotors listed below and a circular screen with a suitable hole size are required.

- in the case of larger samples, a 3- or 5-liter external collection container (Cyclone) can be installed on the device. The grinder can also be equipped with a feeder with a vibrating tongue, which ensures uniform dosing of the sample.

| Specifications: | ZM 300 |

|---|---|

| Material feed size: | < 10 mm |

| Final fineness: | < 40 µm |

| Sample volume max.: | 250 ml, 900 ml (cassette), 3000 ml, 5000 ml (Cyclone) |

| Speed: | 6.000 – 23.000 rpm |

| Power consumption: | 1.750 Watt |

| Dimensions: | 452 x 431 x 426 mm |

| Weight: | 38 kg |

| Rotor material: | stainless steel, titanium, stainless steel with wear-resistant coating |

| Rotors tooth numbers: | 6, 12, 24 |

| Sieve material: | stainless steel, titanium, stainless steel with wear-resistant coating |

| Sieve types: | reinforced rim, Distance (for heat sensitive materials) |

related products

Stainless steel rotors with 6, 12 or 24 teeth. The 12-teeth rotor can also be made of titanium.

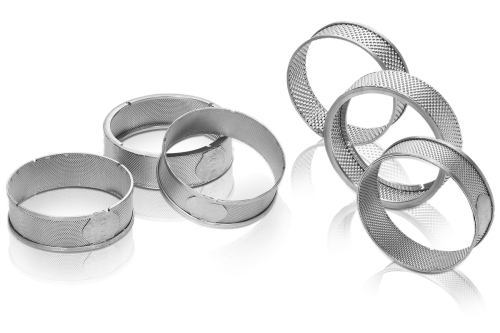

More informationsRing sieves for ZM 300 type mill. Material: stainless steel,stainless steel with a wear-resistant coating, or titanium.

More informations