VELP Oxitest oxidation reactor for testing the aging of materials

Velp Scientifica

Request a price

Testing of the oxidative stability of foods, cosmetic products, fats and oils as described in the AOCS Cd 12c-16 international standard without sample preparation (fat and oil removal)!

Applications e.g.

- Prediction of oxidative stability during shelf life testing

- Examination of the adequacy of the storage conditions

- Choosing the right packaging

- Comparison of the oxidative stability of foods produced in different ways

- Assessment of the effectiveness of antioxidants

- Raw material and final product quality tests, freshness of food raw materials, product warranty period,

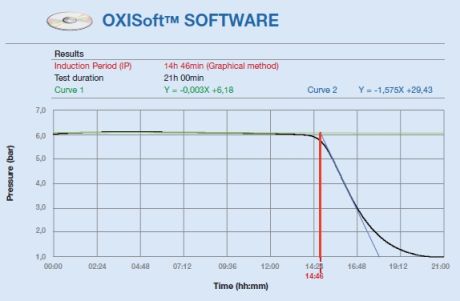

More detailsVELP's OXITEST rapid stability testing device has two independent oxidation cells, so parallel measurements can be performed simultaneously. The OxiSoft computer software supplied with the device can control 4 devices at the same time. With its help, databases can be created, different measurements can be easily compared by displaying the data simultaneously, and the data can be exported. The computer is provided by the user.

Features for safe operation:

- Overpressure safety valve

- Alarm if the sensor is damaged or the temperature range is exceeded

The device can be controlled remotely by connecting to the VELP Ermes Cloud Platform, reports can be created and shared, software can be updated, etc. All this from a computer, tablet or smart phone, even from home.

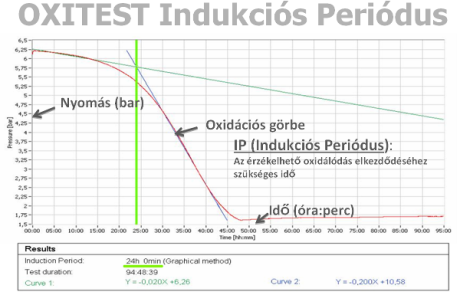

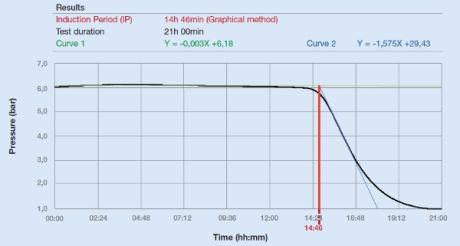

Operating principle: Oxitest carries out accelerated oxidation of the inserted sample at high temperature (typically 90°C) and 6 bar oxygen pressure, while continuously measuring the oxygen pressure in the cells, which, as the oxidation reactions progress, leads to a so-called decreases after the induction period. The final result of the measurement is the so-called oxidation time (induction period), during which - starting from the start of the test - the oxygen pressure in the measuring chamber drops by 10 percent. Its value depends on e.g. the freshness and warranty period of the sample.

A clearly visible change in the oxidation curve is obtained in the case of 2-4% unsaturated fatty acid content of the samples.

The titanium raw material of the measuring cells ensures excellent thermal conductivity and chemical resistance.

Contents of the sales package (in addition to the basic device):

- 331.10002948 OxiSoft, PC software

- 331.10003134 USB cable

- 331.10001985 sample holder (6 pc)

- 331.10001984 spacer (4 pc)

Velp Oxitest technical data:

| Specifications: | Velp Oxitest |

|---|---|

| Number of oxidation chambers: | 2 |

| Chamber capacity: | max. 100 ml |

| Temperature range: | ambient temp. - 120 °C |

| Pressure range: | 0 - 8 bar |

| Consumption: | 900 W |

| Dimensions: | 365 x 485 x 190 mm |

| Weight: | 16.5 kg |

related products

290 liter climate test chamber with active humidity control

More informationsSmall-volume ovens that can be heated up to 1100°C

More informations